A.T.S. is qualified supplier for resistance welding electrodes, in copper alloy, molded, called CAPS.

In resistance welding, this particular type of copper alloy electrodes, being molded and therefore produced in greater quantities but with a reduced number of processes, have the advantage of being cheaper than the common electrode models.

CAPS copper alloy electrodes, in fact, are particularly used for those applications that require a strong wear of the electrode during the welding cycle or in robotic welding systems.

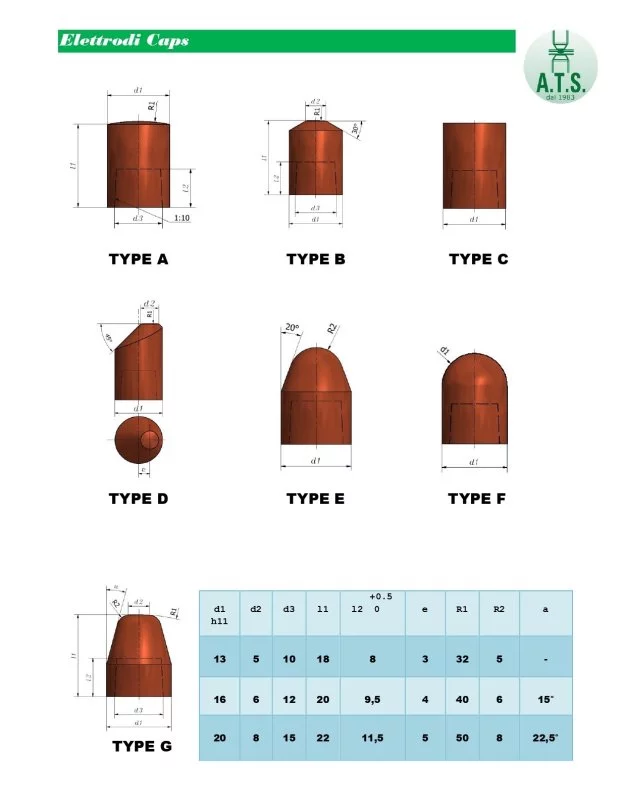

There are several models of CAPS electrodes, which differ from each other in the geometry of the electrode tip itself.

We switch from the electrode CAPS in copper alloy with flat tip to those with radial tip; this differentiation allows in fact to use the electrode geometrically better for each type of welding.

The most substantial difference between the electrode CAPS and TIPS, both printed electrodes, lies in the cone of the electrode itself.

In fact, the CAPS electrodes have a female cone that will be grafted into its male conical seat, while the TIPS electrodes are equipped with a male cone that will then be grafted into its female conical seat.